Best Stone Finishes for Commercial Spaces

Commercial spaces demand materials that withstand constant foot traffic, daily wear and tear, and changing weather conditions while maintaining an aesthetic appeal.

Choosing the right stone finish is critical in creating a welcoming, durable, low-maintenance environment. Whether you are an architect, a property developer, or a business owner, selecting the perfect stone finish can transform your space into one that impresses visitors and serves functional needs.

Below, we examine the best stone finishes tailored for commercial spaces, ensuring your project balances beauty, practicality, and longevity.

1. Honed Finish

A honed finish delivers a smooth, matte surface, ideal for commercial spaces needing elegance without excessive shine. Unlike polished stone, which can be overly reflective, honed stone offers a refined, modern look.

Picture an office lobby or retail store—high traffic demands flooring that stays sophisticated with minimal upkeep. The lack of gloss hides dirt and scratches, reducing cleaning needs.

Perfect for hotels, banks, and offices, honed limestone, marble, or granite exude a premium yet professional vibe.

It’s also great for staircases, balancing safety and style. A honed finish is a smart choice for businesses prioritising aesthetics and practicality.

2. Flamed Finish

If your commercial space includes an outdoor area—whether a restaurant patio, public plaza, or shopping mall entrance—you need a natural stone finish that can handle the elements. The flamed finish is designed precisely for this purpose. Created by exposing the stone to intense heat and then rapidly cooling it, this technique results in a durable, rough, textured surface.

Imagine the footpath leading to your hotel or the walkway outside a shopping centre. These areas must withstand rain, extreme heat, and continuous traffic—all while ensuring pedestrian safety. A flamed finish provides the ideal solution. The textured surface prevents slipping, making it perfect for wet conditions, such as around pools, commercial building entrances, and outdoor terraces.

Beyond practicality, the rugged look of a flamed finish adds a natural, organic appeal to commercial landscapes. Whether designing a modern industrial-style café or a large-scale public park, this finish ensures longevity without compromising aesthetics.

3. Leathered Finish

A leathered finish is the perfect blend of luxury and practicality for commercial spaces. It enhances the stone’s natural texture with a matte, velvety feel while resisting smudges and fingerprints.

Ideal for high-traffic areas like hotel desks, restaurant bars, and office spaces, it offers elegance with minimal upkeep.

Picture a bustling café or upscale restaurant—surfaces must withstand constant use without losing their refined look.

Beyond functional areas, this finish is popular for office and retail accent walls, adding depth and warmth. For businesses seeking durability with a sophisticated touch, leathered stone is a smart investment.

4. Brushed Finish

A brushed finish is the perfect blend of character and functionality. Created by treating the stone with a wire brush to give it a subtly textured surface, this finish enhances the natural grain while ensuring a soft, weathered look. It’s a go-to option for commercial spaces that aim for a modern, rustic, or industrial aesthetic.

Think about boutique retail stores, craft breweries, or contemporary office spaces—these environments benefit from the worn-in, vintage charm that brushed stone provides. Unlike high-gloss finishes, a brushed surface can disguise minor imperfections over time, making it an ideal choice for areas that experience high foot traffic.

Beyond its aesthetic advantages, brushed stone is also practical. It’s a good fit for both indoor and outdoor applications. Whether it’s a hotel lobby with a warm, inviting feel or a stairway in an urban co-working space, this finish delivers durability with character.

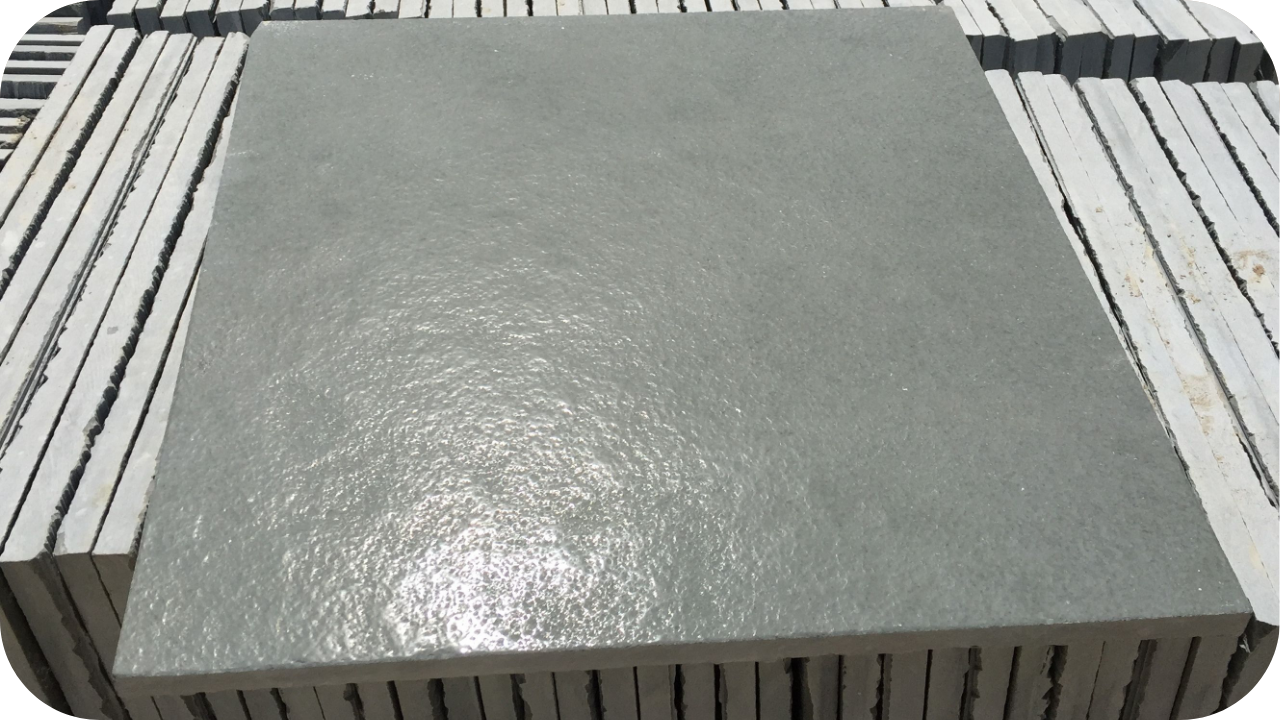

5. Bush-Hammered Finish

Safety is crucial when designing commercial spaces with heavy foot traffic. A bush-hammered finish offers a highly textured surface, making it ideal for pool areas and high-traffic zones. Created by pounding the stone with a specialised hammer, this rough texture enhances grip, reducing slip risks.

Picture a public square, university walkway, or train station entrance—these areas need durable, safe materials. Even in the rain, bush-hammered stone ensures traction, making it a go-to for outdoor malls, hospitals, and pedestrian areas.

Its rugged texture also adds bold character to facades, contrasting beautifully with modern glass exteriors. For safety and style, this finish is a standout choice.

6. Sandblasted Finish

A sandblasted finish delivers a weathered yet refined appearance, making it a popular choice for interior and exterior commercial applications. This technique creates a uniform, finely textured look that reduces glare while maintaining a contemporary aesthetic. It is achieved by blasting the stone surface with high-pressure sand.

Consider a modern retail store façade or an office building’s feature wall. These spaces require visually striking materials yet subtle enough to complement modern architectural elements. A sandblasted finish achieves this balance. The soft, non-reflective surface ensures that light is diffused rather than harsh. It is ideal for environments that prioritise ambience, such as art galleries, upscale boutiques, and executive suites.

Beyond aesthetics, the durability of a sandblasted finish makes it perfect for commercial outdoor spaces. Whether used in plazas, public seating areas, or building exteriors, it resists weathering and requires minimal upkeep. If you want to create a refined yet robust space, sandblasted stone offers a timeless solution.

Conclusion

Your commercial space deserves a stone finish that blends durability with timeless elegance. Whether you need a sleek office lobby or a statement feature wall for your outdoor surface, the right finish makes all the difference. At Splendour in Stone, we offer premium stone solutions tailored to your project’s needs. Let’s create a space that impresses, lasts, and performs effortlessly.

Visit Splendour in Stone today and explore our exceptional range of finishes designed for commercial excellence. Your perfect stone solution starts here!