Why you Should use Stone Pavers for your Patio

Is your current patio a constant source of frustration? Are you tired of battling cracked concrete, uneven slabs, and weeds that seem to sprout overnight?

These unsightly issues not only detract from the beauty of your garden but can also create a hazardous tripping hazard for your family and guests.

Imagine a patio that’s as durable as it is beautiful. Stone pavers offer a long-lasting, low-maintenance solution that will transform your outdoor space into an elegant and inviting retreat.

1. Aesthetic Appeal

Stone pavers offer a timeless beauty that can transform any patio into an elegant outdoor retreat. Their natural textures and varied colours create a visually appealing surface that complements architectural style.

Whether you prefer a rustic charm or a sleek, modern look, stone pavers provide endless design possibilities to match your vision.

The versatility of stone pavers is unmatched. You can choose from various materials such as limestone, marble, bluestone, and granite, each offering unique aesthetic qualities. These pavers can be arranged in different patterns, from classic herringbone to contemporary geometric layouts, allowing you to personalise your patio’s appearance.

Moreover, stone pavers age gracefully, developing a patina that enhances their natural beauty. This enduring quality ensures that your patio will remain attractive for years without frequent replacements.

The rich, earthy tones and unique textures of stone pavers create a harmonious connection between your patio and the surrounding landscape, enhancing the overall ambience of your outdoor space.

2. Durability and Longevity

Durability is key when it comes to patios. Stone pavers are renowned for their exceptional strength and longevity, which are ideal for high-traffic outdoor areas.

Unlike other materials, stone pavers can withstand extreme weather conditions, from scorching summers to freezing winters, without cracking or deteriorating.

One of the primary benefits of stone pavers is their resistance to wear and tear. They can handle heavy loads and constant foot traffic, ensuring your patio remains intact and beautiful for years.

Granite and limestone are mainly known for their hardness and resilience. They provide a sturdy surface that resists chipping and scratching.

Stone pavers are easy to repair. If a paver does become damaged, it can be replaced individually without disturbing the surrounding area, maintaining the overall integrity of your patio. This feature not only saves time but also reduces long-term maintenance costs.

Their durability and longevity mean that once installed, your patio will require minimal upkeep, allowing you to enjoy a beautiful and functional outdoor space with peace of mind.

3. Low Maintenance

One significant advantage of stone pavers is their low maintenance requirements. Once installed, stone pavers demand minimal upkeep, allowing you to enjoy your patio without needing cleaning or repairs. This is a substantial benefit for homeowners seeking both beauty and convenience.

Thanks to their natural composition, stone pavers are inherently resistant to stains and dirt. Regular sweeping and occasional washing with water are needed to keep them pristine. For tougher stains, a mild detergent and a brush will usually do the trick, avoiding the need for harsh chemicals.

In addition, stone pavers are resistant to mould and mildew, which can be common issues with other materials, especially in damp or shaded areas. This resistance ensures that your patio remains clean and safe without frequent scrubbing or the application of anti-fungal treatments.

Another key benefit is that individual pavers can be easily replaced if damaged. This avoids extensive repairs or complete resurfacing, saving both time and money.

4. Versatility in Design

Stone pavers offer unparalleled versatility in design, allowing you to create a patio that perfectly matches your aesthetic preferences and functional needs. With a wide range of materials, colours, and textures available, stone pavers can be tailored to complement any architectural style, from traditional to contemporary.

One of the standout features of stone pavers is their ability to be arranged in various patterns. Whether you prefer the classic elegance of a herringbone pattern, the clean lines of a linear layout, or the intricate charm of a mosaic design, stone pavers provide the flexibility to achieve your desired look. This adaptability enables you to personalise your patio, making it a unique extension of your home.

Stone pavers offer abundant colour options, ranging from earthy browns and warm tans to cool greys and sophisticated blacks. This variety allows you to choose hues harmonising with your landscape and exterior design.

Moreover, stone pavers can create distinct zones within your patio, such as seating areas, walkways, and dining spaces. This zoning capability ensures that your patio is beautiful and highly functional, catering to various activities and gatherings.

5. Eco-Friendly Option

Choosing stone pavers for your patio is not only a stylish decision but also an eco-friendly one. Stone pavers are made from natural materials and have a lower environmental impact than synthetic alternatives.

This sustainable choice contributes to preserving natural resources and reducing your carbon footprint.

Stone pavers are highly durable, meaning they have a long lifespan and require fewer replacements. This longevity reduces the need for frequent production and transportation of new materials, further minimising environmental impact.

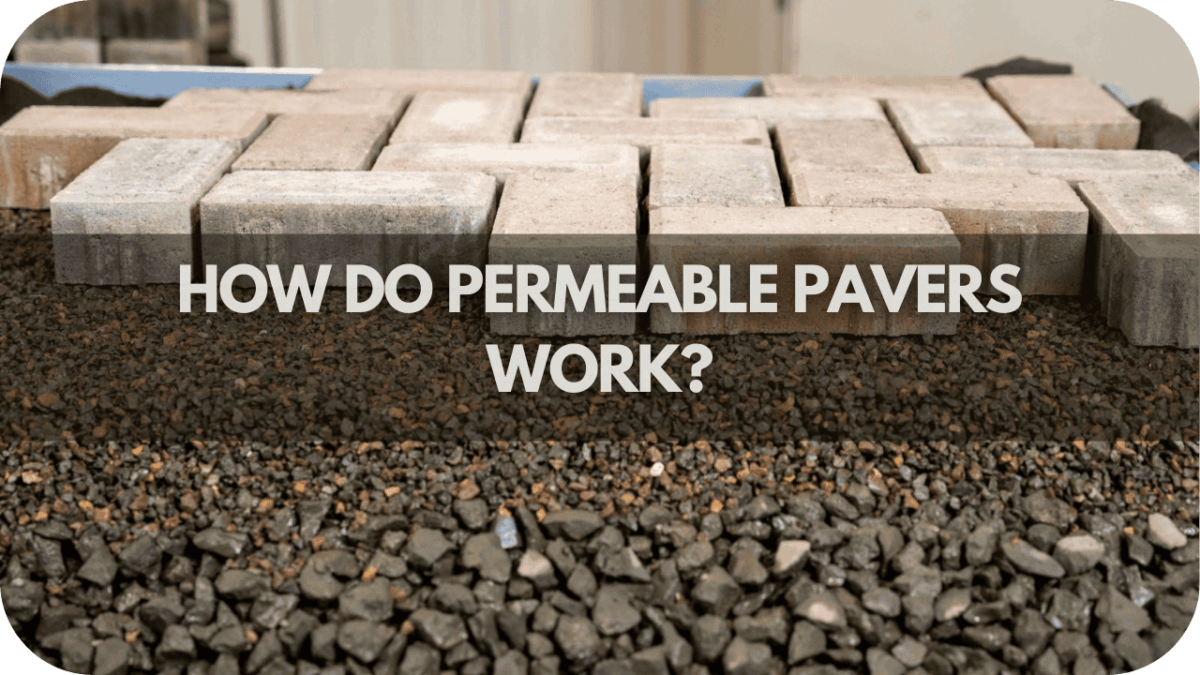

Another eco-friendly aspect of stone pavers is their permeability. Natural stone allows water to seep through, reducing runoff and promoting groundwater recharge. This helps manage stormwater and prevent erosion, making stone pavers an excellent choice for eco-conscious homeowners.

Another key benefit is recyclability. At the end of their life cycle, stone pavers can be repurposed or recycled, avoiding landfill waste. This contributes to a circular economy, where materials are continuously reused and recycled.

6. Increased Property Value

Investing in stone pavers for your patio can significantly increase your property’s value. Potential buyers are often drawn to homes with well-designed, attractive outdoor spaces, and a patio with stone pavers can be a major selling point.

Stone pavers’ timeless appeal and high-end look elevate your property’s overall aesthetic, making it more desirable to prospective buyers.

Stone pavers are durable and low-maintenance, which adds to their appeal. Buyers appreciate features requiring minimal upkeep and a long lifespan, translating to fewer future expenses and less effort in maintaining the property. The robust nature of stone pavers ensures that your patio will remain in excellent condition for many years, providing lasting value.

Customisation options for stone pavers also play a crucial role in boosting property value. With various patterns, colours, and materials, you can create a unique outdoor space that stands out. This personalisation can make your home more memorable and attractive in a competitive real estate market.

7. Enhanced Outdoor Living Space

Using stone pavers for your patio can significantly enhance your outdoor living space, transforming it into a functional and inviting area for relaxation and entertainment.

Stone pavers offer a versatile foundation for creating various zones within your patio, such as seating areas, dining spaces, and walkways, making your outdoor area more usable and enjoyable.

The aesthetic appeal of stone pavers adds a touch of elegance and sophistication to your patio. Their natural textures and colours seamlessly blend with the surrounding landscape, creating a harmonious and visually pleasing environment.

This integration with nature enhances the overall ambience, making your outdoor space a true extension of your home.

Customisation options with stone pavers allow you to design a patio that suits your needs and style preferences.

From various shapes and sizes to intricate patterns and layouts, stone pavers provide endless possibilities for personalisation, ensuring your outdoor living space reflects your unique taste.

8. Heat Resistance

One of the standout features of stone pavers is their excellent heat resistance, making them an ideal choice for patios, especially in regions with hot climates. Unlike other materials, stone pavers remain cool underfoot even on scorching summer days, ensuring your outdoor space stays comfortable and inviting.

Natural stone’s inherent properties allow it to dissipate heat effectively, preventing it from becoming excessively hot. This means you can walk barefoot on your patio without the discomfort of burning your feet, making it a pleasant space for relaxation and activities throughout the day.

Certain types of stone, such as limestone and sandstone, are mainly known for their superior heat resistance. These stones have a light colour that reflects sunlight, further contributing to their cool surface temperature. This feature enhances comfort and helps reduce the heat island effect around your home.

The heat-resistant nature of stone pavers also contributes to the longevity and durability of your patio. By resisting heat-induced cracks and damage, stone pavers maintain their structural integrity over time, reducing the need for repairs and replacements.

Conclusion

Stone pavers offer timeless elegance and enduring practicality. Invest in the beauty of a stone patio and transform your outdoor space into a haven of relaxation and style. Picture yourself enjoying this tranquil oasis for years to come – start planning your dream patio today!